Defect Analyses and Improvement Strategies of Aluminum Alloy Die Castings (Part Two)

2.2.2 Improvement measures for shrinkage cavities

In order to eliminate the shrinkage cavity of aluminum alloy die casting parts, the wall thickness of the shrinkage cavity's position of the part can be appropriately reduced, so that the molten metal can be solidified and formed in a uniform state and the part's mold can also be optimized and perfected to eliminate shrinkage cavities. However, in some industrial manufacturing processes, the accuracy requirements for the parts are relatively high, and it is impossible to eliminate the shrinkage cavity by reducing the wall thickness. In this case, the method of increasing the depth of the prefabricated hole can be adopted. Combining the analysis of the process angle, the cooling water ways can be added at the mold position where shrinkage cavities easily occur. The cooling effect and solidification speed of the part can be improved, thereby effectively reducing the generation of shrinkage cavities and controlling shrinkage cavities at the non-important position of the part.

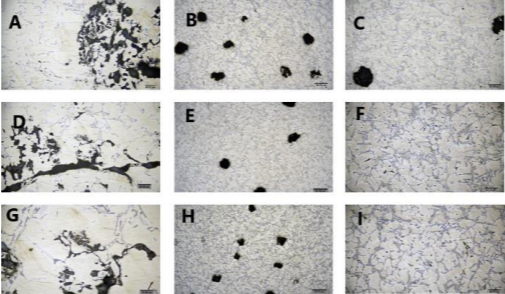

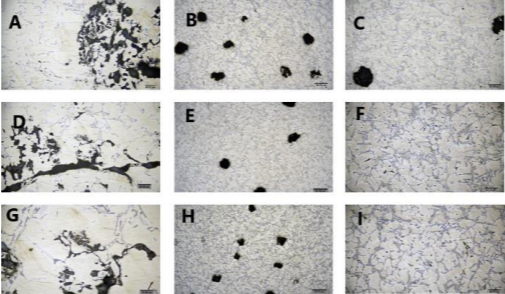

2.3 Inclusions

2.3.1 The specific role of iron, manganese and chromium

Aluminum alloys will produce various heavy elements in the process of high-temperature smelting. These heavy elements accumulate for a long time to form solid compounds which are deposited in the furnace hearth to become slags. These slags contain iron, manganese and chromium, which will form crystals with a relatively hard structure under the action of temperature. In the process of die casting of parts, crystals will mix with the aluminum alloy liquid to form inclusions. In addition, iron, manganese and chromium crystals have high melting points, so they usually do not change under the action of high temperature, which is one of the reasons why their deposits in the furnace hearth are increasing. Slag deposition will directly affect the quality of aluminum alloy die casting parts. For example, in the process of aluminum alloy die casting parts, slags will increase the hard points of the parts, thereby reducing the fluidity of the aluminum alloy liquid. Once iron, manganese and chromium are combined, the structure of die casting parts with more iron content can be changed from needle-like crystals to cubic crystals based on the actual situation, which are beneficial to comprehensively improve the hardness and strength of the die casting parts.

2.3.2 Oxide inclusions

2.3.2 Oxide inclusions

There are two types of oxides in die casting of parts: primary oxides and secondary oxides. Among them, the primary oxide mainly refers to that the aluminum alloy is not slagged in the high-temperature smelting process, resulting in a large quantity of oxides remaining in the aluminum alloy liquid, so these oxides are directly processed with the part at the same time. The secondary oxide refers to the compound produced by the contact of turbulence flow and air during the die casting of the part, which is processed with the part together after entering the aluminum alloy liquid.

2.3.3 Improvement measures of inclusions

First, in the process of aluminum alloy die casting parts, it is necessary to control the content of aluminum in a reasonable range to ensure that the content of heavy metals meets the standard, and at the same time strengthen the examination of materials. Second, regularly clean the aluminum alloy smelting hearth to avoid slag deposits. It is necessary to reduce vibration as far as possible during the operation of the aluminum alloy liquid. On the one hand, it can effectively prevent the oxides from mixing with the aluminum alloy liquid, and on the other hand, it can reduce their contact with the air to produce oxides. Finally, all the aluminum alloy liquid to be transferred must be subjected to the slagging treatment. If the aluminum alloy needs to be continuously poured for smelting, the time for the slagging treatment needs to be set according to the specific conditions. When the molten metal is poured, the speed should be reduced to avoid turbulence.

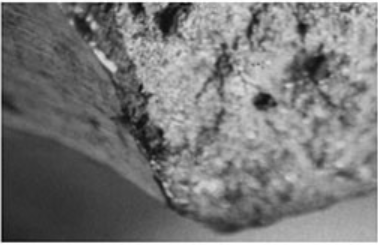

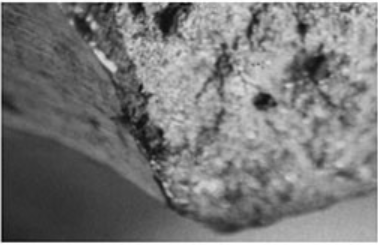

2.4 Cracks

2.4 Cracks

2.4.1 The main reason for cracks

In the process of die casting parts, if the aluminum alloy contains a large amount of magnesium, it will make the aluminum alloy stick to the mold more. This situation will lead to serious pulling in the ejection process, resulting in cracks. In addition, if there is no change in the composition of the aluminum alloy, cracks will also occur in die-cast parts under the action of high temperature, and at the same time, there will be shrinkage porosity around cracks. In the solidification and shaping process of aluminum alloy die casting parts, the internal and external shrinkage of the parts will cause tensile stress because of the cooling sequence, which is also one of the main reasons for the cracking of the parts.

2.4.2 Improvement measures of cracks

In the process of aluminum alloy die casting parts, if the content of magnesium is too high, pure aluminum ingots can be appropriately added to neutralize the aluminum alloy composition, effectively increasing its silicon content and reduce its magnesium content. In order to avoid the problem of cracks caused by high mold temperature, a cooling device can be added to the mold to effectively reduce the mold temperature and control the temperature in a balanced state. In order to prevent the aluminum alloy parts from being cracked due to the pulling force in the ejection process, the part structure can be appropriately changed in the manufacturing process of parts, thereby reducing the difficulty of ejection of parts.

3. Conclusion

The causes of quality problems such as gas holes, shrinkage holes, inclusions and cracks in aluminum alloy die casting parts are analyzed, and specific solutions are proposed, hoping to lay a good foundation for improving the level of die casting parts.

In order to eliminate the shrinkage cavity of aluminum alloy die casting parts, the wall thickness of the shrinkage cavity's position of the part can be appropriately reduced, so that the molten metal can be solidified and formed in a uniform state and the part's mold can also be optimized and perfected to eliminate shrinkage cavities. However, in some industrial manufacturing processes, the accuracy requirements for the parts are relatively high, and it is impossible to eliminate the shrinkage cavity by reducing the wall thickness. In this case, the method of increasing the depth of the prefabricated hole can be adopted. Combining the analysis of the process angle, the cooling water ways can be added at the mold position where shrinkage cavities easily occur. The cooling effect and solidification speed of the part can be improved, thereby effectively reducing the generation of shrinkage cavities and controlling shrinkage cavities at the non-important position of the part.

2.3 Inclusions

2.3.1 The specific role of iron, manganese and chromium

Aluminum alloys will produce various heavy elements in the process of high-temperature smelting. These heavy elements accumulate for a long time to form solid compounds which are deposited in the furnace hearth to become slags. These slags contain iron, manganese and chromium, which will form crystals with a relatively hard structure under the action of temperature. In the process of die casting of parts, crystals will mix with the aluminum alloy liquid to form inclusions. In addition, iron, manganese and chromium crystals have high melting points, so they usually do not change under the action of high temperature, which is one of the reasons why their deposits in the furnace hearth are increasing. Slag deposition will directly affect the quality of aluminum alloy die casting parts. For example, in the process of aluminum alloy die casting parts, slags will increase the hard points of the parts, thereby reducing the fluidity of the aluminum alloy liquid. Once iron, manganese and chromium are combined, the structure of die casting parts with more iron content can be changed from needle-like crystals to cubic crystals based on the actual situation, which are beneficial to comprehensively improve the hardness and strength of the die casting parts.

2.3.2 Oxide inclusions

2.3.2 Oxide inclusionsThere are two types of oxides in die casting of parts: primary oxides and secondary oxides. Among them, the primary oxide mainly refers to that the aluminum alloy is not slagged in the high-temperature smelting process, resulting in a large quantity of oxides remaining in the aluminum alloy liquid, so these oxides are directly processed with the part at the same time. The secondary oxide refers to the compound produced by the contact of turbulence flow and air during the die casting of the part, which is processed with the part together after entering the aluminum alloy liquid.

2.3.3 Improvement measures of inclusions

First, in the process of aluminum alloy die casting parts, it is necessary to control the content of aluminum in a reasonable range to ensure that the content of heavy metals meets the standard, and at the same time strengthen the examination of materials. Second, regularly clean the aluminum alloy smelting hearth to avoid slag deposits. It is necessary to reduce vibration as far as possible during the operation of the aluminum alloy liquid. On the one hand, it can effectively prevent the oxides from mixing with the aluminum alloy liquid, and on the other hand, it can reduce their contact with the air to produce oxides. Finally, all the aluminum alloy liquid to be transferred must be subjected to the slagging treatment. If the aluminum alloy needs to be continuously poured for smelting, the time for the slagging treatment needs to be set according to the specific conditions. When the molten metal is poured, the speed should be reduced to avoid turbulence.

2.4 Cracks

2.4 Cracks2.4.1 The main reason for cracks

In the process of die casting parts, if the aluminum alloy contains a large amount of magnesium, it will make the aluminum alloy stick to the mold more. This situation will lead to serious pulling in the ejection process, resulting in cracks. In addition, if there is no change in the composition of the aluminum alloy, cracks will also occur in die-cast parts under the action of high temperature, and at the same time, there will be shrinkage porosity around cracks. In the solidification and shaping process of aluminum alloy die casting parts, the internal and external shrinkage of the parts will cause tensile stress because of the cooling sequence, which is also one of the main reasons for the cracking of the parts.

2.4.2 Improvement measures of cracks

In the process of aluminum alloy die casting parts, if the content of magnesium is too high, pure aluminum ingots can be appropriately added to neutralize the aluminum alloy composition, effectively increasing its silicon content and reduce its magnesium content. In order to avoid the problem of cracks caused by high mold temperature, a cooling device can be added to the mold to effectively reduce the mold temperature and control the temperature in a balanced state. In order to prevent the aluminum alloy parts from being cracked due to the pulling force in the ejection process, the part structure can be appropriately changed in the manufacturing process of parts, thereby reducing the difficulty of ejection of parts.

3. Conclusion

The causes of quality problems such as gas holes, shrinkage holes, inclusions and cracks in aluminum alloy die casting parts are analyzed, and specific solutions are proposed, hoping to lay a good foundation for improving the level of die casting parts.

Related News

- Impact of Heat Treatment on Mechanical Properties and Thermal Conductivity of ZL102 Alloy

- Impact of T6 Heat Treatment on ADC12 Aluminum Alloy Properties

- Enhancing the Mechanical Properties of ADC12 Aluminum Alloy via T6 Heat Treatment

- Die-Casting Process Design of Valve Bodies for Automobile Oil Cylinder Parts

- Temperature Field Simulation & Optimization of Automotive Housing Die Castings

- Research Status of High-Impact Aluminum Alloys Domestically and Internationally

- Die-cast Aluminum Castings for High-speed Rail Rocker Arm Shells

- Aluminum Alloys for Automobile Body Panels

- Analysis and Measures of Internal Shrinkage Cavities in Aluminum Die Castings

- Advantages of Aluminum Alloys in Lightweight Automobiles