Effect of Rheological Die Casting on Properties of ADC12 Aluminum Alloys

The high-pressure die-cast process is widely used in the production of parts in the fields of automobiles, electronics, and aerospace. Compared with the traditional casting process, it has the characteristics of high productivity, low energy consumption and complex formed parts. However, the die-cast process is to inject molten aluminum alloy into the cavity under high pressure, resulting in metal reaction and air trapped inside the casting, and bubbles and oxide inclusions are prone to appear inside the part. To reduce the above-mentioned defects in the traditional die-cast process and improve the performance of die-cast parts, researchers have introduced a semi-solid die-cast process. Many studies have reported that semi-solid die casting improves the performance of die castings and the quality of die castings. Since semi-solid die casting can provide a fluid with better viscosity, and the temperature of filling the mold is low, the amount of entrained air is greatly reduced, thereby reducing the pores and oxide inclusions in the filling process, and achieving the effect of improving the mechanical properties of the casting. Semi-solid forming is generally divided into semi-solid thixoforming and semi-solid rheological forming. The cost is too high and industrial production is difficult due to the long process of thixoforming and the difficulty in storage and transportation of semi-solid slurry. The semi-solid rheological forming process which has the characteristics of short process flow, energy saving and material saving, and low cost has become a hot topic.

ADC12 aluminum alloy is widely used in the automotive industry due to its high casting performance, low shrinkage, and good corrosion resistance. However, there are few reports on rheological die casting of ADC12 aluminum alloy so far. JANUDOM and others successfully prepared ADC12 aluminum alloy semi-solid slurry by the gas-induced semi-solid (GISS) method, and die-cast commercial parts. HU and others successfully prepared ADC12 semi-solid die-cast aluminum alloy by combining mechanical stirring to prepare slurry and high-pressure die-casting. However, these methods require additional equipment and significantly increase the cost.

This topic takes ADC12 aluminum alloy as the research object. To simplify the forming process and shorten the process, the die-cast machine is slightly modified, and a die-cast system combining semi-solid slurry preparation with inclined plate method and high-pressure die casting is designed. For the gating system of the casting, the microstructure at different positions was studied, and the mechanical properties of rheological die-cast ADC12 aluminum alloy were studied.

1. Test materials and methods

1.1 Materials

The material used is a commercial ADC12 aluminum alloy. The chemical composition of the alloy measured by an X-ray fluorescence spectrometer (XRF) is shown in Table 1.

Table 1 Chemical composition of ADC12 aluminum alloy wb/%

ADC12 aluminum alloy is widely used in the automotive industry due to its high casting performance, low shrinkage, and good corrosion resistance. However, there are few reports on rheological die casting of ADC12 aluminum alloy so far. JANUDOM and others successfully prepared ADC12 aluminum alloy semi-solid slurry by the gas-induced semi-solid (GISS) method, and die-cast commercial parts. HU and others successfully prepared ADC12 semi-solid die-cast aluminum alloy by combining mechanical stirring to prepare slurry and high-pressure die-casting. However, these methods require additional equipment and significantly increase the cost.

This topic takes ADC12 aluminum alloy as the research object. To simplify the forming process and shorten the process, the die-cast machine is slightly modified, and a die-cast system combining semi-solid slurry preparation with inclined plate method and high-pressure die casting is designed. For the gating system of the casting, the microstructure at different positions was studied, and the mechanical properties of rheological die-cast ADC12 aluminum alloy were studied.

1. Test materials and methods

1.1 Materials

The material used is a commercial ADC12 aluminum alloy. The chemical composition of the alloy measured by an X-ray fluorescence spectrometer (XRF) is shown in Table 1.

Table 1 Chemical composition of ADC12 aluminum alloy wb/%

| Si | Cu | Zn | Fe | Mg | Mn | Al |

| 10.78 | 10.78 | 0.696 | 0.884 | 0.265 | 0.234 | The rest |

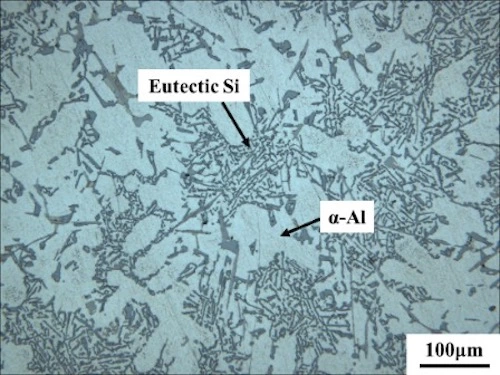

Figure 1 is the gravity casting structure of the ADC12 aluminum alloy used in the test. Its structure is mainly composed of a white dendritic α-Al phase and a black needle-like eutectic Si phase.

Figure 1 Gravity casting microstructure of ADC12 aluminum alloys

1.2 Preparation of semi-solid slurry and die casting process

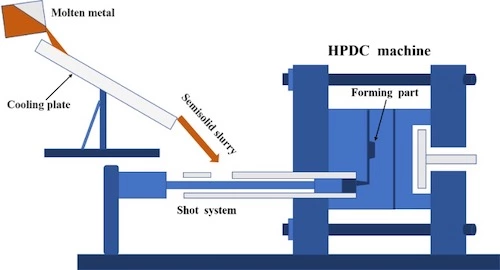

The inclined plate rheological die casting process is shown in Figure 2. During the test, the ADC12 ingot was first placed in a graphite crucible and melted at 620°C; at the same time, graphite paint was coated on the surface of the inclined plate, in which the material of the inclined plate was No.45 steel; the length was 100cm, and the inclination angle was 30°. Adjust the bracket to ensure that the molten metal flows accurately from the tail end of the inclined plate to the gate of the die-casting machine; preheat the cavity of the die-casting machine to 200°C. After the melt is degassed and the slag removed, it is poured from the top of the inclined plate. After the cooling of the inclined plate and its gravity, the semi-solid slurry is formed and directly flows into the feed port of the die-cast machine. The temperature of the slurry was measured with a thermocouple, and when the temperature dropped to 560 to 570°C, die casting was performed, and open the mold to take out the sample.

Figure 2 The schematic diagram of inclined plate rheological die-cast ADC12 aluminum alloys

Related News

- Industrialization of the Composite 3D Printing for General Motors

- Porsche and GM Have Obtained Achievement in 3D Printing Auto Parts Technology

- Development of Aluminum Alloy Die Castings for Automobile Steering Knuckles (Part Two)

- Development of Aluminum Alloy Die Castings for Automobile Steering Knuckles (Part One)

- Die Casting Technologies of Automobile Structural Parts (Part Three)

- The Die Casting Technology of Automobile Structural Parts (Part Two)

- The Die Casting Technology of Automobile Structural Parts (Part One)

- Application of Heat-Free Aluminum Alloys to Integrated Die-Casting

- Mechanical Properties and Microstructure of Heat-Free Alloys

- Designing Die-Cast Molds for Complex Shells