Tesla's One-piece Die-cast Molding Makes Traditional Car Companies Silent

I have to admit that Tesla is a star car company with popularity, and every move will be interpreted as "subverting tradition" and "challenging the future". After Tesla's Shanghai Gigafactory announced that the large-scale die-cast machine was put into mass production, it was interpreted as being highly technical but impractical by many people.

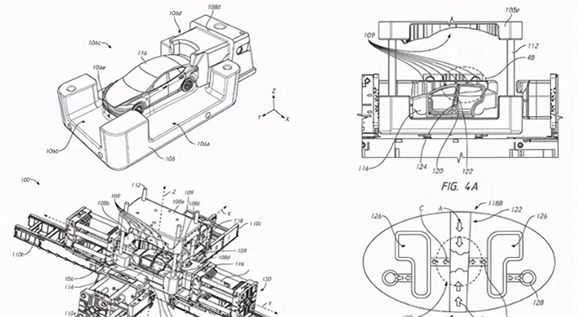

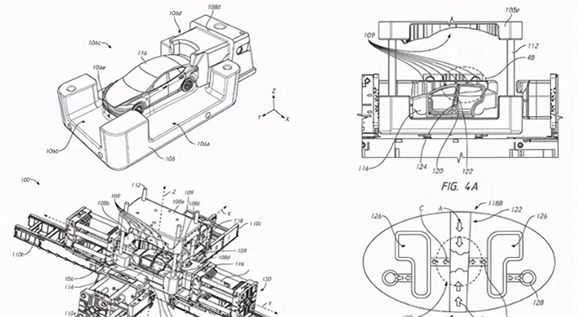

This may be due to Musk's evaluation of the integrated die casting completed in the Fremont factory: "This is the largest die-cast machine in the world, which can make the rear of the body integrally formed." Therefore, many people think that the car is divided into two parts, that is the front and the rear. The rear is integrally formed, which is some kind of powerful technology. Many media publicity manuscripts that promote one-sided advantages of integrated die casting, such as building a car like a toy. In fact, the one-piece die casting is not so untraditional, or so great.

In fact, the one-piece part can be seen as part of the rear floor assembly. The specific location is under the rear seat. What does it do? It is the floor, which is used to place something, and it is not the part that is primarily involved in the safety of the structure. When a building collapses, everyone will say that the foundation beams are not strong enough, and no one will say that the floor is not strong enough, right? Therefore, Tesla's only purpose in using one-piece die-cast on this part is to reduce costs in three aspects. As a comparison, let's us know how traditional car companies other than Tesla do it from another angle.

Tesla says that its one-piece die casting can reduce the original more than 70 parts to 2. Hearing this, if you have dealt with the production line, you can understand the economic value at once, as Tesla announced to the public. The pouring of 2 parts only takes 90 seconds and requires 2 sets of molds. It takes more than 2 hours for 70 parts with stamping and welding for ordinary car companies, which has great cost value for the equipment, site, labor, production rhythm, inspection and logistics required in upstream and downstream production.

However, if integrated die casting has all the advantages, traditional car companies are willing to adopt the technology with a cost space of 20%. I think Tesla's 90 seconds is reasonable, but the punching, stamping and welding of 70 parts for traditional car companies will not take 2 hours. For punching and stamping, it only takes about 1 second to weld for simple profiles. The rear floor assembly is mainly spot welded, and there are not too many long welding seams. Of course, if it is calculated from the upper conveyor belt to the lower conveyor belt for each part, it may take up to 2 hours before entering the next process.

The above is not to refute Tesla's advantages. It is irrefutable that the time required for welding die castings of 2 parts is less than that of 70 parts, but it is not so exaggerating; at least not so exaggerating that the car manufacturer is going to update equipment and processes. In addition, although die casting is a one-piece molding, it sounds like it is better, but in fact, the process control is more difficult, and it is far less mature than cold stamping.

The above picture is gravity pouring, while die casting has extra main injection and pressurization processes. However, the above picture can illustrate a certain problem. The casting has far less control over the details of the parts than the processing and assembly of the parts. Unless it is a situation that is not complicated in shapes and only considers strength, such as engine blocks, steering knuckles and other large parts.

Since aluminum is injected and pressurized after melting, factors such as thermal expansion and cold contraction have to be considered. An unreasonable temperature change process may also affect the strength consistency of parts. The above are the reasons why traditional car companies do not use integrated die casting. The quality and consistency of a mature steel mill with mature stamping and welding are still in the hands of quality engineers. To make changes, the entire industry must have new supporting facilities and a process of exploration, which is not worth it. Therefore, Tesla's integrated rear floor die casting is not enough to stun traditional car companies. Many of them have evaluated the pros and cons of this process, and finally chose to give up or use it in small-sized or special parts instead of such a large and complex assembly.

However, die casting has an advantage that cannot be ignored, and it is also the only driving force for Tesla to do this, that is, costs. The application of die casting to larger and more complex assemblies will bring greater cost benefits, at least starting with double digits. Moreover, the incidental income will be infinitely amplified in the production rhythm of electric vehicles. In the end, Tesla's goal must be to press a car head, press a car rear, and weld the battery on the floor.

Of course, with the current level of technology, Tesla has only applied one-piece die casting parts to the parts of Model Y, which is an attempt and accumulation of experience. For traditional car companies, there is no incentive to make much changes, unless the core interests are challenged. For example, everyone is a B-class car, and Tesla's cost is half of yours. With the purpose of only discussing technology, Tesla's new technology may not have many advantages at present, but it is likely to affect the direction of the industry.

This may be due to Musk's evaluation of the integrated die casting completed in the Fremont factory: "This is the largest die-cast machine in the world, which can make the rear of the body integrally formed." Therefore, many people think that the car is divided into two parts, that is the front and the rear. The rear is integrally formed, which is some kind of powerful technology. Many media publicity manuscripts that promote one-sided advantages of integrated die casting, such as building a car like a toy. In fact, the one-piece die casting is not so untraditional, or so great.

In fact, the one-piece part can be seen as part of the rear floor assembly. The specific location is under the rear seat. What does it do? It is the floor, which is used to place something, and it is not the part that is primarily involved in the safety of the structure. When a building collapses, everyone will say that the foundation beams are not strong enough, and no one will say that the floor is not strong enough, right? Therefore, Tesla's only purpose in using one-piece die-cast on this part is to reduce costs in three aspects. As a comparison, let's us know how traditional car companies other than Tesla do it from another angle.

Tesla says that its one-piece die casting can reduce the original more than 70 parts to 2. Hearing this, if you have dealt with the production line, you can understand the economic value at once, as Tesla announced to the public. The pouring of 2 parts only takes 90 seconds and requires 2 sets of molds. It takes more than 2 hours for 70 parts with stamping and welding for ordinary car companies, which has great cost value for the equipment, site, labor, production rhythm, inspection and logistics required in upstream and downstream production.

However, if integrated die casting has all the advantages, traditional car companies are willing to adopt the technology with a cost space of 20%. I think Tesla's 90 seconds is reasonable, but the punching, stamping and welding of 70 parts for traditional car companies will not take 2 hours. For punching and stamping, it only takes about 1 second to weld for simple profiles. The rear floor assembly is mainly spot welded, and there are not too many long welding seams. Of course, if it is calculated from the upper conveyor belt to the lower conveyor belt for each part, it may take up to 2 hours before entering the next process.

The above is not to refute Tesla's advantages. It is irrefutable that the time required for welding die castings of 2 parts is less than that of 70 parts, but it is not so exaggerating; at least not so exaggerating that the car manufacturer is going to update equipment and processes. In addition, although die casting is a one-piece molding, it sounds like it is better, but in fact, the process control is more difficult, and it is far less mature than cold stamping.

The above picture is gravity pouring, while die casting has extra main injection and pressurization processes. However, the above picture can illustrate a certain problem. The casting has far less control over the details of the parts than the processing and assembly of the parts. Unless it is a situation that is not complicated in shapes and only considers strength, such as engine blocks, steering knuckles and other large parts.

Since aluminum is injected and pressurized after melting, factors such as thermal expansion and cold contraction have to be considered. An unreasonable temperature change process may also affect the strength consistency of parts. The above are the reasons why traditional car companies do not use integrated die casting. The quality and consistency of a mature steel mill with mature stamping and welding are still in the hands of quality engineers. To make changes, the entire industry must have new supporting facilities and a process of exploration, which is not worth it. Therefore, Tesla's integrated rear floor die casting is not enough to stun traditional car companies. Many of them have evaluated the pros and cons of this process, and finally chose to give up or use it in small-sized or special parts instead of such a large and complex assembly.

However, die casting has an advantage that cannot be ignored, and it is also the only driving force for Tesla to do this, that is, costs. The application of die casting to larger and more complex assemblies will bring greater cost benefits, at least starting with double digits. Moreover, the incidental income will be infinitely amplified in the production rhythm of electric vehicles. In the end, Tesla's goal must be to press a car head, press a car rear, and weld the battery on the floor.

Of course, with the current level of technology, Tesla has only applied one-piece die casting parts to the parts of Model Y, which is an attempt and accumulation of experience. For traditional car companies, there is no incentive to make much changes, unless the core interests are challenged. For example, everyone is a B-class car, and Tesla's cost is half of yours. With the purpose of only discussing technology, Tesla's new technology may not have many advantages at present, but it is likely to affect the direction of the industry.

Related News

- Impact of Heat Treatment on Mechanical Properties and Thermal Conductivity of ZL102 Alloy

- Impact of T6 Heat Treatment on ADC12 Aluminum Alloy Properties

- Enhancing the Mechanical Properties of ADC12 Aluminum Alloy via T6 Heat Treatment

- Die-Casting Process Design of Valve Bodies for Automobile Oil Cylinder Parts

- Temperature Field Simulation & Optimization of Automotive Housing Die Castings

- Research Status of High-Impact Aluminum Alloys Domestically and Internationally

- Die-cast Aluminum Castings for High-speed Rail Rocker Arm Shells

- Aluminum Alloys for Automobile Body Panels

- Analysis and Measures of Internal Shrinkage Cavities in Aluminum Die Castings

- Advantages of Aluminum Alloys in Lightweight Automobiles